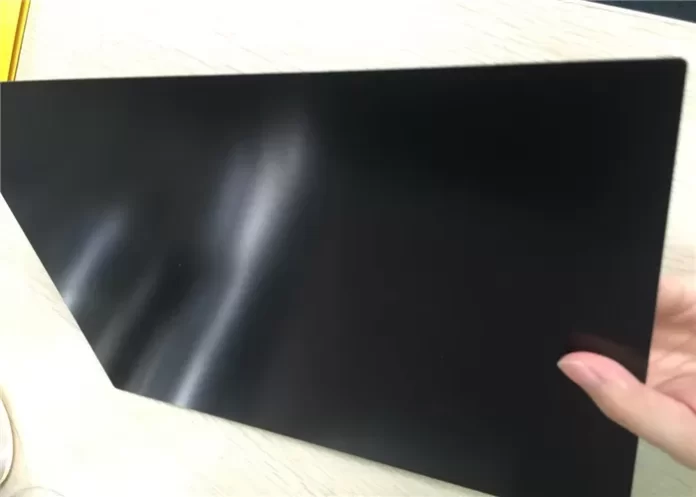

Black anodized aluminum sheets are a type of metal that is made from a layer of aluminum that has been treated so that it has a black coating. This type of coating is used to give the metal a more durable, corrosion-resistant surface. Black anodized aluminum sheets are also used to make parts that will be exposed to the elements, such as exterior surfaces of vehicles or aircraft.

What are black anodized aluminum sheets?

Black anodized aluminum sheets are a type of aluminum that has been treated with a black oxide finish. This finish makes the aluminum more resistant to corrosion and provides a solid look and feel. Black anodized aluminum is often used in areas where aesthetic considerations are important, such as in aerospace and automotive applications. It is also used in industries that require resistance to corrosion, such as chemical plants.

Anodizing is a process that is used to coat aluminum with a black oxide finish. Black oxide is a type of coating that is very resistant to corrosion. The finish provides a solid look and feels to the aluminum, and it also helps to protect the metal from damage caused by elements such as salt water.

Black anodized aluminum sheets can be cut, drilled, and machined just like other types of aluminum. However, because the finish is so resistant to corrosion, it is important to keep the aluminum clean if you are planning on using it in a wet environment.

What are satin anodized aluminum sheets?

Satin anodized aluminum sheets are a type of aluminum that has been treated with a special anodizing process that creates a very smooth, shiny surface. This type of aluminum is often used for product packaging or other decorative purposes because of its high shine and lustre.

Some common uses for satin anodized aluminum sheets include:

-Product packaging

-Decorative accents on furniture or walls

-Feature elements on cars or motorcycles

What are their uses?

Black anodized aluminum sheets are a type of metal that has been treated with an oxide material to darken its color. This treatment can make the metal stronger and more resistant to corrosion, so black anodized aluminum sheets are often used in construction and industrial applications. They can also be used in products that need to resist wear and tear, such as car parts.

Silver anodized aluminum sheets are a type of metal that has been treated with an oxide material to create a silver color. Silver anodized aluminum sheets are often used in products that need to reflect light, such as sunglasses and bike parts.

Aluminum is also often used in products that need to be lightweight and durable, such as beer cans and airplane parts.

Pros and Cons of Black Anodized Aluminum Sheets

Black anodized aluminum sheets are a type of aluminum that has been treated with an electroless nickel-chrome plating process. This treatment results in a black color, which gives the aluminum a unique look and adds to its strength and durability. Some of the benefits of using black anodized aluminum sheets include their resistance to corrosion and their ability to withstand high temperatures.

However, black anodized aluminum sheets do have some drawbacks. They are not as light as other types of aluminum, so they may be more expensive to purchase and transport. Additionally, they may not be compatible with some paint or coating applications.

Conclusion

Black anodized aluminum sheets are a type of metal that has been treated to create a black color. This treatment is done in order to improve the sheet’s ability to resist corrosion, which makes it ideal for use in applications where protection from water and other elements is important. Applications for black anodized aluminum sheets include aircraft parts, power plant equipment, and medical devices.